Josie King

الموقع الإلكترونيwww.josiekingdesign.com

Instagram:josiekingdesign

المهاراتصنع تجربة عبر أدوات اليد والكهرباء ، من التقليدي إلى التكنولوجي. استخدام كل شيء من الخشب والمعدن والبلاستيك والراتنجات والسيراميك والخردة والوحل! طريقة غريبة لاستكشاف جميع جوانب صنع.

كخريج حديث في Goldsmiths Design ، تمتد عملي العملي متعدد التخصصات من الأثاث إلى الأفلام ، بدءًا من المنحوتات وحتى التصميم. لدي حب للمادة وأنا دائما تبحث عن ألعاب جديدة للعب! في السنة الأخيرة من شهادتي ، قضيت سنة في صنع الأثاث من الوحل (ولكن في الغالب مجرد الفوضى). أحب تعلم مهارات جديدة وجعل الأشياء التي أعتقد أنها غريبة أو مضحكة ، أو بعض الاختراعات المذهلة هنا!

تقارير المشاريع التي أضيفت مؤخراً

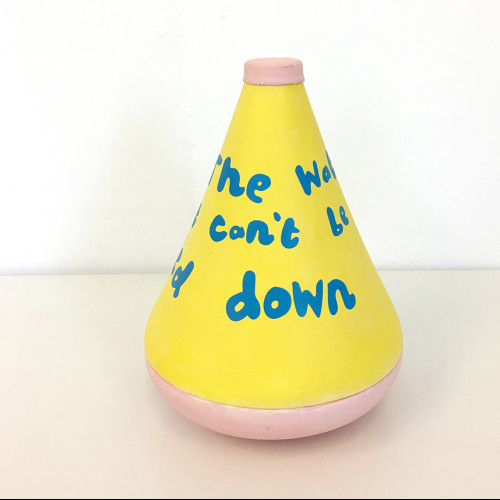

One the bottle had been printed I needed to coat it in resin. This is because 3d printing creates quite an open structure making it very light, but not quite watertight! I painted each piece in layers upon layers of coloured resin, sanding back and each layer to get a smooth surface. I then traced Taye's bubble writing into a file for the vinyl cutter so I could stick his writing on the bottle. Finally, I attached a screw thread and lid from an existing water bottle to the top coating that in resin too before varnishing the entire thing.

With such a complex and precise shape the best approach would not be by hand but through 3d printing. This would allow me to construct the shape as a whole on the computer before slicing it into the two parts I needed so that I could have both an enclosed bottle and an open dish for the concrete to sit. This approach allowed me to be super accurate and to do things like making sure the top of the bottle fitted the standard neck of water bottle tops so I could add a screw thread in.

My first approach is always to use hand techniques, initially I thought to turn the egg/cone shape from wood using a lathe, then to slice into the two parts I needed, the bottle and the weighted base. Next to vacuum form these shapes to create a plastic shell. However I ran into some problems, the size of the shape would be too large to vacuum form in the accuracy that I needed, furthermore it would be difficult and time consuming to acheive the exact shape on the lathe. Then I had the additional issue of how the two parts may fit together as the vacuum forming does not allow for the ledges and notches I would need for it to hold together.